UNS S31254/F44 is a 6Mo super austenitic stainless steel with a density of 8.24 g/cm3 and a typical PREN of 42 ~ 44, ensuring that it is designed for impact toughness, resistance to chloride crevice corrosion, stress corrosion cracking and pitting. It combines good mechanical strength and high ductility to provide excellent corrosion resistance in a variety of environments. In the annealed state, the yield strength exceeds 44 KSI (300Mpa).

1.Available products and implementation standards

- Plate - Seamless and welded pipes - Pipe fittings - flange - forging - Bars - Other profiles and processed parts | - ASTM A240, EN10088 - ASTM A312, ASTM A358 - ASTM A403 - ASTM A182 - ASTM A182 - ASTM A276 |

Delivery Status:

- Plates: solution, pickling, trimming;

- Seamless tube: solid solution + acid white, length can be fixed;

- Welded pipe: solid solution acid white + RT% flaw detection, can also be polished inside and outside

- Forgings: annealing + polishing;

- The bar is in a forged, polished or turned surface;

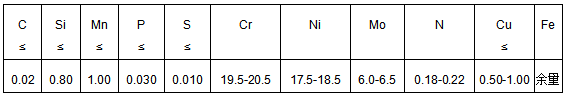

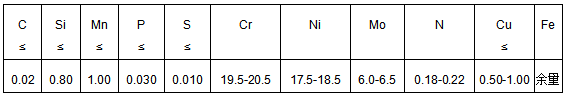

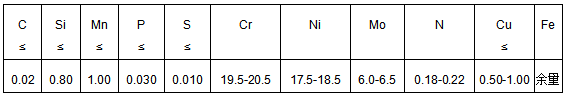

2. Chemical composition wt.%

254SMo, S31254, F44, 1.4547, X1CrNiMoN20-18-7, NORSOK R11 to R15

3.Mechanical properties

Typical mechanical properties in the annealed state

4.Typical Applications

S31254 super austenitic stainless steel is widely used in marine structure, seawater desalination, seawater heat exchange, environmental protection, energy, electric power, oil refining and chemical equipment, salt and soy sauce brewing, paper industry equipment, etc., including:

- Distillation columns

- Exhaust gas scrubbers

-water pump

-Chokes

-valve

-pipeline

- Flanges and manifolds

- Bleaching equipment in the pulp and paper industry

-Heat exchanger

UNS S31254/F44 is a 6Mo super austenitic stainless steel with a density of 8.24 g/cm3 and a typical PREN of 42 ~ 44, ensuring that it is designed for impact toughness, resistance to chloride crevice corrosion, stress corrosion cracking and pitting. It combines good mechanical strength and high ductility to provide excellent corrosion resistance in a variety of environments. In the annealed state, the yield strength exceeds 44 KSI (300Mpa).

1.Available products and implementation standards

- Plate - Seamless and welded pipes - Pipe fittings - flange - forging - Bars - Other profiles and processed parts | - ASTM A240, EN10088 - ASTM A312, ASTM A358 - ASTM A403 - ASTM A182 - ASTM A182 - ASTM A276 |

Delivery Status:

- Plates: solution, pickling, trimming;

- Seamless tube: solid solution + acid white, length can be fixed;

- Welded pipe: solid solution acid white + RT% flaw detection, can also be polished inside and outside

- Forgings: annealing + polishing;

- The bar is in a forged, polished or turned surface;

2. Chemical composition wt.%

254SMo, S31254, F44, 1.4547, X1CrNiMoN20-18-7, NORSOK R11 to R15

3.Mechanical properties

Typical mechanical properties in the annealed state

4.Typical Applications

S31254 super austenitic stainless steel is widely used in marine structure, seawater desalination, seawater heat exchange, environmental protection, energy, electric power, oil refining and chemical equipment, salt and soy sauce brewing, paper industry equipment, etc., including:

- Distillation columns

- Exhaust gas scrubbers

-water pump

-Chokes

-valve

-pipeline

- Flanges and manifolds

- Bleaching equipment in the pulp and paper industry

-Heat exchanger

UNS S31254/F44 is a 6Mo super austenitic stainless steel with a density of 8.24 g/cm3 and a typical PREN of 42 ~ 44, ensuring that it is designed for impact toughness, resistance to chloride crevice corrosion, stress corrosion cracking and pitting. It combines good mechanical strength and high ductility to provide excellent corrosion resistance in a variety of environments. In the annealed state, the yield strength exceeds 44 KSI (300Mpa).

1.Available products and implementation standards

- Plate - Seamless and welded pipes - Pipe fittings - flange - forging - Bars - Other profiles and processed parts | - ASTM A240, EN10088 - ASTM A312, ASTM A358 - ASTM A403 - ASTM A182 - ASTM A182 - ASTM A276 |

Delivery Status:

- Plates: solution, pickling, trimming;

- Seamless tube: solid solution + acid white, length can be fixed;

- Welded pipe: solid solution acid white + RT% flaw detection, can also be polished inside and outside

- Forgings: annealing + polishing;

- The bar is in a forged, polished or turned surface;

2. Chemical composition wt.%

254SMo, S31254, F44, 1.4547, X1CrNiMoN20-18-7, NORSOK R11 to R15

3.Mechanical properties

Typical mechanical properties in the annealed state

4.Typical Applications

S31254 super austenitic stainless steel is widely used in marine structure, seawater desalination, seawater heat exchange, environmental protection, energy, electric power, oil refining and chemical equipment, salt and soy sauce brewing, paper industry equipment, etc., including:

- Distillation columns

- Exhaust gas scrubbers

-water pump

-Chokes

-valve

-pipeline

- Flanges and manifolds

- Bleaching equipment in the pulp and paper industry

-Heat exchanger

Our AdvantageOur Vulcan Metals (VCM) team with sound metallurgy knowledge and vast cross-industry projects experience, is committed to provide sophisticated technical and commercial solutions for your...

Our AdvantageOur Vulcan Metals (VCM) team with sound metallurgy knowledge and vast cross-industry projects experience, is committed to provide sophisticated technical and commercial solutions for your...